|

Detailinformationen |

|||

| Chemische Zusammensetzung: | Magnesium | Material: | Magnesiummetall |

|---|---|---|---|

| Form: | DSR-Form | Kernmaterial: | Stahl |

| Gewicht: | 32 Pfund | Zusammensetzung der Hinterfüllung: | 75 % Gips, 20 % Bentonit, 5 % Natriumsulfat |

| Offen-Stromkreisspannung: | 1,70-1,75 V | Ruhespannung: | 1,57–1,62 V |

| Tatsächliche Kapazität: | ≥ 1.100 Ah/g | Aktuelle Effizienz: | ≥ 50% |

| Aluminiuminhalt: | < 0,01% | Mangan-Inhalt: | 0,5-1,30 % |

| Eisengehalt: | ≤ 0,03% | Nickelinhalt: | ≤ 0,001% |

| Kupfergehalt: | ≤ 0,02% | ||

| Hervorheben: | D S R Shape Magnesium Anode,Backfill Powder Sacrificial Anode,Alloy Metal Prepacked Magnesium Anode |

||

Produkt-Beschreibung

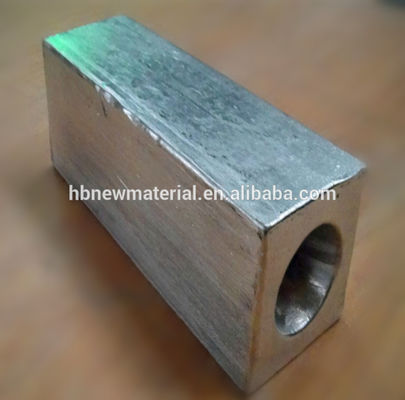

Prepacked Magnesium Anode for Anti Corrosion and Cathodic Protection

Product Specifications

Commodity: Prepacked Magnesium Anode with backfill powder

Weight: 32 lb. High-Potential Magnesium Anode - Bare

Type: Pre-packaged type in a cloth bag

Production Standard: ASTM G-97

Backfill Mixture Composition

| Component | Percentage |

|---|---|

| Ground Hydrant Gypsum | 75% |

| Powdered Bentonite | 20% |

| Hydratate Sodium Sulphate | 5% |

Chemical Compositions of Cast Magnesium Anode (%)

| Element | High potential | AZ63B | AZ63C | AZ63D |

|---|---|---|---|---|

| Al | < 0.01 | 5.30-6.70 | 5.30-6.70 | 5.0-7.0 |

| Zn | --- | 2.50-3.50 | 2.50-3.50 | 2.0-4.0 |

| Mn | 0.5-1.30 | 0.15-0.70 | 0.15-0.07 | 0.15-0.70 |

| Si (max) | 0.05 | 0.10 | 0.30 | 0.30 |

| Cu (max) | 0.02 | 0.02 | 0.05 | 0.10 |

| Ni (max) | 0.001 | 0.002 | 0.003 | 0.003 |

| Fe (max) | 0.03 | 0.005 | 0.005 | 0.005 |

| Others each | 0.05 | --- | -- | --- |

| Others total | 0.30 | 0.30 | 0.30 | 0.30 |

| Mg | Balance | Balance | Balance | Balance |

Electrochemical Properties of Cast Magnesium Anodes

| Item | Open-circuit Voltage (-V) | Close-circuit Voltage (-V) | Actual capacitance (A.h/g) | Current efficiency (%) |

|---|---|---|---|---|

| High Potential | 1.70-1.75 | 1.57-1.62 | ≥ 1.100 | ≥ 50 |

| Low Potential (AZ63) | 1.50-1.55 | 1.45-1.50 | ≥ 1.105 | ≥ 50 |

Note: Open and Close-circuit voltage is relative to Saturated Calomel Electrode (SCE)

Environmental Features

Made of recyclable materials or easily decomposable materials with harmful element content below safety standards, ensuring no pollution to the surrounding environment.

Available cable types: PVC/PVC, XLPE/PVC, HMWPE etc. with any required size.

Backfill Element Safety Standards

| Element | Maximum Content |

|---|---|

| Cadmium (Cd) | ≤ 1ppm |

| Arsenicum (As) | ≤ 1ppm |

| Mercury (Hg) | ≤ 1ppm |

| Phosphorus (Pb) | ≤ 10ppm |

Performance Advantages

The magnesium anode is cast from high-purity magnesium and installed in a specialized backfill mixture. This configuration produces an open circuit potential of 1.65-1.70 volts, offering 20-30% greater protection than conventional magnesium anodes. The higher driving voltage enables superior protection with fewer anodes.

Packaging & Shipping

Packaged on pallets with steel bundles for secure transportation.

Company Information

We represent a leading anode manufacturing plant in China, specializing in magnesium and aluminum anodes. With annual exports of approximately 3000 metric tons primarily to Canada and the USA, our products undergo rigorous third-party testing in the USA to ensure consistent quality. Our direct access to raw material resources enables us to offer competitive pricing while maintaining high standards.

Facility Images

Frequently Asked Questions

What do Magnesium sacrificial anodes do?

Magnesium sacrificial anodes prevent metal corrosion in salt/fresh water or soil through cathodic protection systems. They are commonly used to protect underground pipelines (gas, oil, water), storage tanks, ships, port facilities, power plants, and irrigation systems. When connected to a structure, the anode corrodes preferentially, protecting the structure from corrosion until replacement is needed.

Why choose us?

With over 20 years in the cathodic protection anode market, we strictly adhere to ASTM G97 standards. Our continuous production of high-quality, stable products helps reduce your long-term costs while ensuring reliable performance.

Company Values

Our belief: Innovation forever

Our spirit: Sincerity, unity, dedication, hard work, creativity

Our mission: Provide most advanced products & most professional technical solutions

Möchten Sie mehr über dieses Produkt erfahren?